About New Century tooling

New Century tooling Co., LTD., founded in 2006, is located in Shen Zhen of China. Our company is a professional mold manufacturer and injection molding manufacturer, equipped with some of the most advanced equipment . now it occupies a land area of 6000 square meters with about 120 employees with an injection molding manufacturing factory and an export mold making factory. On the other hand, we possess a highly technical management team who has the professional knowledge and solid experience, including project development and management, design and fabrication, plan and control, process control and TQC, etc.

Our company offers variety of products which can meet your multifarious demands. We adhere to the management principles of “quality first, customer first and credit-based” since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

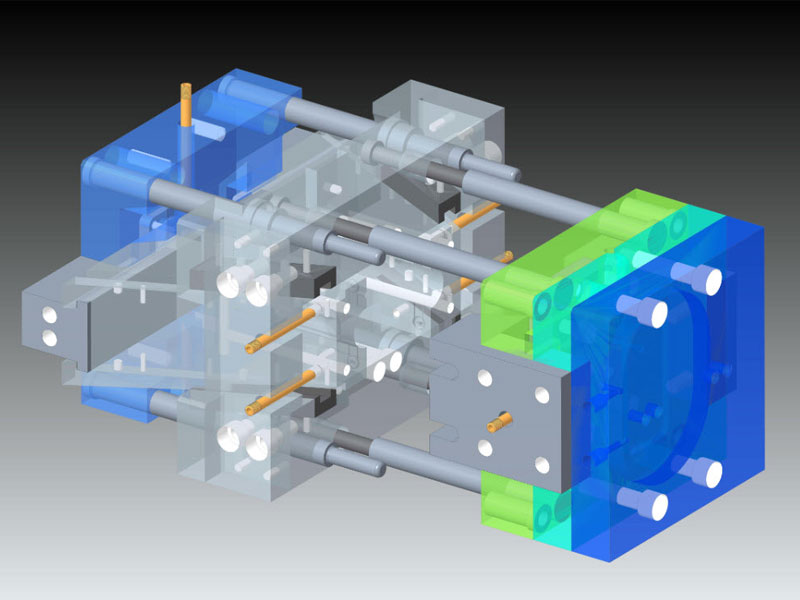

New Century is specializing in injection molding manufacturing with 35 normal machines + 2pcs of 2K injection machines and building precision injection molds, complex & big size injection moulds, and precision metal tools, such as multi-cavitation molds, unscrewing molds, double color injection molds, health care products molds, DME MUD inserts molds . The related industry includes automotive products, electronic products, medical products, and household products ECT.

Product Development & Mold Design Capacity

New Century has more than 20 designer for product Product Development & Mold Design , that we have rich experience for various products, efforts excellent and fact the services of Development & Mold Design and strong technical support for customers.

Manufacturing Capacity

New Century has 15pcs of high steep CNC machines, 10pcs of fine EDM cutting machines, 5pcs of precision grinding machines ,1pcs of projector, 2 pcs of CMM machines and 35 normal machines + 2pcs of 2K injection machines to make sure the quality and manufacturing capacity with tolerance with 0.005mm and Manufacturing Capacity with 40~50 molds per month and with that we can make biggest mold with 25 tons.

Quality Control

We are committed to ensuring the quality of our products as well as improving it. We never hesitate to take any preventive and corrective measures whenever and wherever problems are found. Our Quality Management System runs through the whole business transaction, which includes: Design review Design verification and validation Electronically controlled calibration control assuring positive and recall keeping Receiving inspection Mandatory documented Quality Planning for each project First Article Inspections In-process inspections including computerized, paperless real time SPC and Process Capability studies Final/last inspection Non-conforming material control that assures timely and positively corrective and preventive action Internal auditing to assure systems remain in compliance Now, we are still optimizing our QA system. We have earned a good reputation as “ship-stock” supplier, but we are still changing for the better. We are always being worthy of your confidence, we guarantee. First, all of our manufacturing sites have earned ISO 9001:2015 Certification, which is rewarded to our contribution to the quality control. Second, Quality Management System is designed to control the quality of the product. And we have internal quality guidebooks, that is, Quality Assurance Manual and Operation Procedure, to normalize the management. Third,our quality management staffs have adequate educational background and rich experience. Personnel involved in the quality management include Quality Engineers, Quality Technicians and Inspectors. We are confident that our QA team will ensure the quality of your product along with the newest equipments, which we are always updating to cater to the demand of customers.

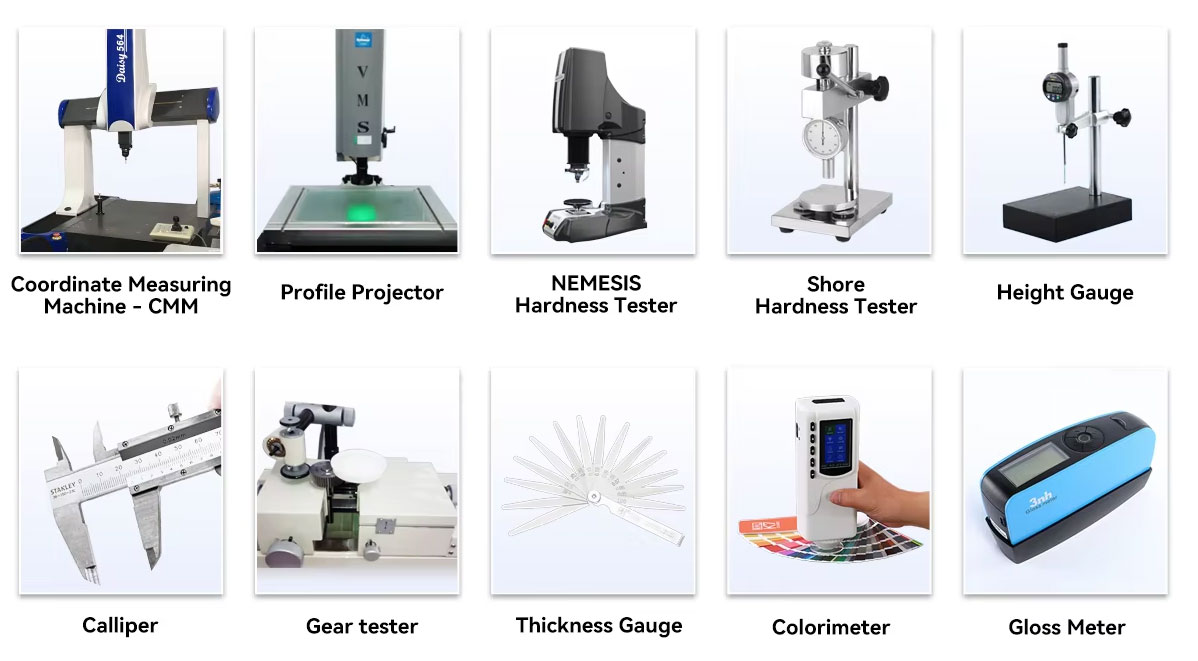

Inspection Facilities:

We are a sophisticated mould supplier for we have adequate quality control capabilities.

We have established professional Quality Assurance Labs, in which well-trained technicians and engineers inspect the quality of products with advanced equipments.

Equipments available for inspection and testing include but are not limited to:

Manual and DCC Coordinate Measuring Machines

Various Optical Comparators Digital Height Gages with measurement ranges up to 40 inches

Datamyte SPC software for real time SPC and capability studies

Customizable Designs

We can create custom molds that meet your specific requirement

Modern Management

ISO9001:2015,and IATF 16949 quality standard, all products are 100% fully inspected

Fast Turnaround

Based on our experienced team and mature supply chain, we can give you faster time-to-market

Rich Experience

Most of our engineers have worked for more than ten years

Quality Control Equipment