The mould opening cycle of an injection mould refers to the time required for the entire development process from mould design to delivery. The length of the cycle is affected by many factors such as mould complexity, processing technology, material selection, and factory resources.

If you don’t know what stages are involved in making an injection mould, some customers may think that the mould making cycle of an injection mould only takes a few days. This article will tell you why an injection mould cannot be made in a few days, but takes dozens of days.

The main stages of the injection moulding cycle

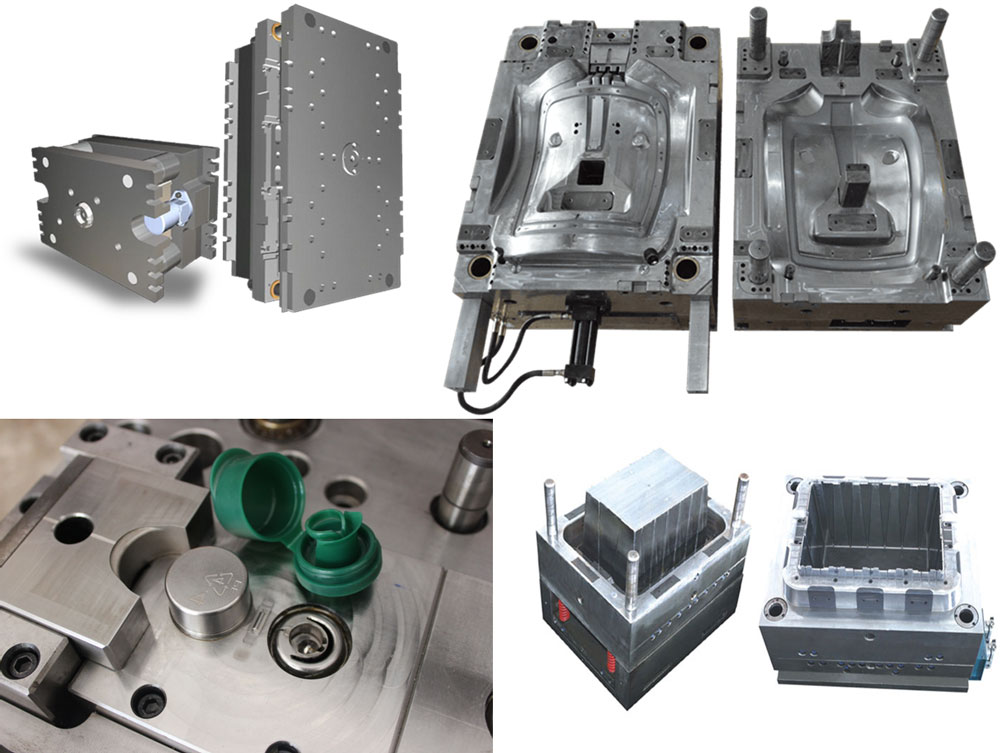

The mould opening cycle of an injection mould can generally be divided into four stages: mould design, mould processing, mould assembly, and mould trial and debugging. Each stage can also be divided into several small stages.

Let‘s look at the mould design first.

Mould design is the core link of mould development. Since the injection mould is produced completely according to the design drawing, whether the mould design is reasonable directly determines the performance, quality and production efficiency of the mould. Specifically, the design of the injection mould can be divided into the following four steps.

1.Demand analysis. According to the product drawings and requirements provided by the customer (such as product material, output, surface treatment, etc.), we analyze how to design and conduct manufacturability analysis, such as checking the uniformity of product wall thickness, demoulding slope, etc., so as to optimize the design to ensure that the mould can be manufactured and meet customer needs.

2.Structural design. The structure of the injection mould includes the parting surface, pouring system, cooling system, ejection system, lateral core pulling mechanism, etc. These structures need to be made in the design drawing without any flaws.

3.Mould flow analysis: Use software such as mouldflow and mouldex3D to simulate filling, cooling, shrinkage, and warping to analyze the rationality of mould design and optimize mould design when necessary.

4.Design review. After the mould drawing is designed, it needs to be sent to the customer for confirmation to see if it meets the customer’s needs. Only after the review is passed can we proceed to the next step.

This stage usually takes about 1-4 weeks.

Some people may question whether it takes so long to design a mould?

In fact, designing a mould can be done quickly, or not, depending on the complexity of the mould structure and customer needs.

If the mould has a simple structure and the customer’s needs are very clear, it can be designed in two or three days or even one or two days. However, if the mould has a complex structure, or the customer’s needs are unclear and the design drawing is required to be revised repeatedly, it will definitely take more time, even a month is not surprising.

Then comes mould processing

Mould processing is the process of turning the mould design drawing into a physical object, which can be divided into steps such as material procurement and rough processing, fine processing, polishing, and heat treatment.

1.Material procurement and rough processing. Select steel (such as P20, 718H, S136, H13, etc.) according to the mould life and product requirements. After the materials are purchased, they need to be cut into mould cores, templates and other blanks of the required size by sawing machines or wire cutting. Then use milling machines or CNC machines to perform preliminary contour processing of mould cores and mould cavities and remove excess materials. This is the rough processing of mould materials.

2.Precision machining. Precision machining generally includes CNC finishing, electrical discharge machining (EDM), drilling and tapping, etc. This is the core step of mould processing, and various structures of the mould are basically completed in this step.

3.Polishing and surface treatment: The cavity surface is mirror polished or textured, and chrome plating, titanium nitride (TiN) and other coatings are used to improve wear resistance or demoulding performance.

4.Heat treatment. Quench and temper the mould to improve hardness and wear resistance, and avoid oxidation deformation through vacuum heat treatment. However, this step is not necessary. Generally, high-hardness steel (such as H13, S136, NAK80) requires quenching + tempering, and transparent moulds (such as S136 mirror polishing) require vacuum heat treatment.

The mould processing cycle is generally 2-8 weeks, which is the most time-consuming part in the mould development process. The length of time is related to factors such as the complexity of the mould, process requirements, and the manufacturer’s production efficiency.

Let’s look at mould assembly

An injection mould is composed of multiple parts, and these parts are generally processed separately. After these parts are made, they need to be assembled, such as installing the mould frame, ejection system, cooling water circuit, etc.

After assembly is completed, it is also necessary to cooperate with the inspection to ensure that the sliding block, inclined top and other moving parts are smooth, to test the cooling and exhaust, to verify the sealing of the water channel and the exhaust effect, to ensure that all parts of the mould can operate normally.

This stage usually takes about 1-3 weeks, but can be longer or shorter.

The last step is the trial mould and adjustment stage

As the saying goes, you can only tell whether a mule is a horse by pulling it out for a walk, and the same is true for injection moulds. Whether the manufactured mould is good or not can only be known by testing it on the injection moulding machine. Therefore, the mould trial is also indispensable, and the mould trial should be carried out at least twice. If problems are found during the mould trial, the mould needs to be repaired.

This stage generally takes 1-4 weeks, and the length of time mainly depends on whether problems are found during the mould trial and the number of mould trials.

Finally, after passing the customer’s acceptance, it enters the delivery stage, and the entire mould opening cycle is basically over.

This whole process takes at least 3-4 weeks, and if the mould is more complicated, it will take longer. Therefore, it is really impossible to make an injection mould and hope to deliver it in a few days. It’s not that we don’t want to, but no one can do it.