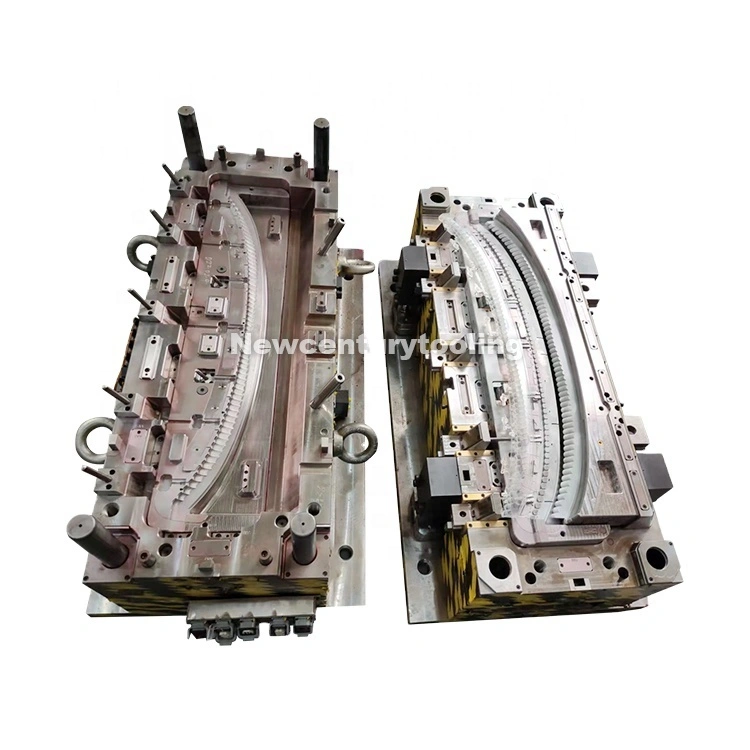

Automotive Injection Mold Tool Customization for Car Bumper Manufacturing

Automotive Injection Mold Tool Customization for Car Bumper Manufacturing involves designing and creating precise molds tailored to produce high-quality, durable car bumpers efficiently. The customization ensures perfect fit, surface finish, and material flow, reducing defects and production time. Key selling points include enhanced product accuracy, reduced manufacturing costs, and faster turnaround to meet specific automotive design requirements.

Precision, Durability, Customization, Efficiency

Our automotive injection mold tool customization ensures precision-crafted injection molded parts for car bumpers, tailored to your exact design and quality standards. Utilizing advanced materials like ABS and PC, along with single or multi-cavity molds, we deliver durable parts with tight tolerances and efficient production cycles. With ISO9001 certification and dedicated customer support, our service guarantees reliable, high-quality components that streamline your manufacturing process.

● Precision

● Durability

● Efficiency

● Reliability

Product Display

Precision, Durability, Efficiency, Innovation

Precision, Durability, Efficiency, Customization

Automotive injection mold tool customization for car bumper manufacturing delivers precision-engineered injection molded parts crafted from diverse materials such as ABS, PC, and PA+GF, ensuring high durability and dimensional accuracy with tolerances up to ±0.01mm. Featuring versatile single or multi-cavity molds equipped with hot or cold runner systems and robust mold materials like NAK80 and 1.2738, these tools support complex shapes and sizes ranging from 5 to 1000mm to meet specific design requirements. This product’s core structure enables high-volume production with mold life spanning 500,000 to 5,000,000 shots, providing reliable, cost-effective solutions tailored for automotive and industrial applications.

◎ Precision Engineering

◎ Flexible Mold Design

◎ Robust Reliability

Material Introduction

The injection molded parts for automotive bumpers are produced using high-quality materials such as ABS, PC, PP, and PA+GF, ensuring durability and excellent impact resistance. These materials are carefully selected to meet the stringent requirements of automotive applications, providing strength and flexibility in the final product. The customization process supports both single and multi-cavity molds, allowing precise control over part quality and consistency.

◎ ABS

◎ PC

◎ PA+GF

FAQ