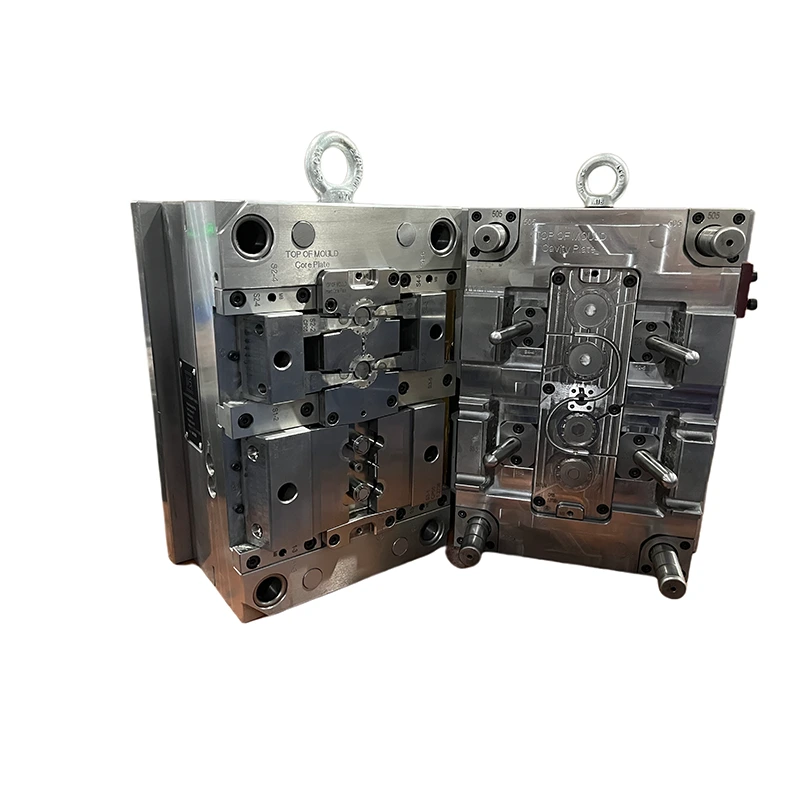

China Multi-Cavity Medical Plastic Injection Mold Design and Manufacturing

In a bustling factory nestled in China’s heartland, precision meets innovation as multi-cavity medical plastic injection molds come to life. Like a symphony of engineering, each mold effortlessly shapes countless intricate medical components with unmatched accuracy and speed, ensuring every piece supports health and safety worldwide. This cutting-edge design and manufacturing process transforms raw plastic into lifesaving tools, proving craftsmanship and technology can heal together.

Precision, Efficiency, Durability, Customization

Our multi-cavity medical plastic injection mold design and manufacturing deliver high-precision injection molded parts with customizable shapes, sizes, and colors to meet strict medical standards. Utilizing advanced materials and equipment, we ensure durable, high-quality components that enhance product reliability and performance. With efficient lead times and one-stop procurement services, customers benefit from seamless production, consistent quality, and timely delivery.

● Precision

● Durability

● Efficiency

● Customization

Enhanced Precision, Efficient Production

Precision, Efficiency, Durability, Scalability

Injection Molded Parts produced through advanced multi-cavity medical plastic injection mold design offer precise dimensional tolerance (±0.01mm) and high durability, supported by premium mold materials such as 1.2738 and NAK80, ensuring extended mold life up to 5 million cycles. These parts utilize a variety of engineering plastics like ABS, PMMA, and PEEK, adapted to diverse industrial and automotive applications, with options for hot or cold runner systems to optimize production efficiency. The structural design facilitates custom sizes from 5 to 1000mm and complex shapes as per client drawings, delivering consistent quality backed by ISO9001:2015 and RoHS certifications.

◎ Precision

◎ Durability

◎ Versatility

Application Scenario

Material Introduction

Injection molded parts produced using multi-cavity medical plastic injection molds are crafted from a wide range of high-performance materials such as ABS, PC, PEEK, and PA+GF, selected for their biocompatibility and durability. These materials ensure precise dimensional stability and meet stringent industry standards, allowing for the production of complex and consistent parts at large volumes. Utilizing advanced mold designs and material selections, the injection molded parts provide reliable performance across various medical and industrial applications.

◎ ABS

◎ PMMA

◎ PEEK

FAQ