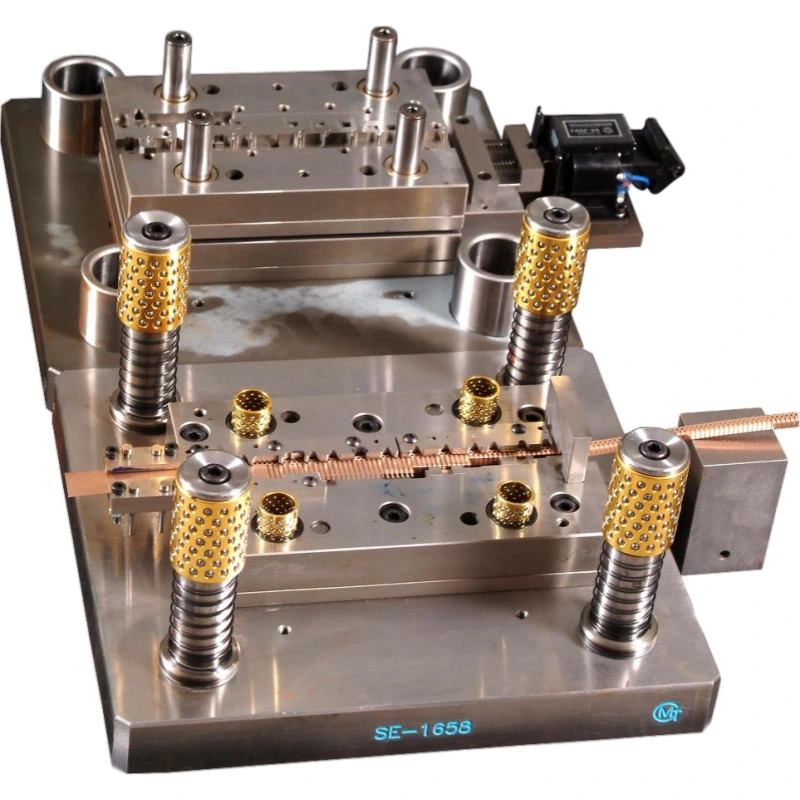

Custom Injection Molded Copper Stamping Die Mold Vehicle Parts of Rolls-Royce

**Article:**

The Custom Copper Stamping Die Mold for Vehicle Parts is a precision tool designed to shape metal components with high accuracy. Made from durable copper, this die mold features a polished finish that ensures smooth stamping and reduces wear. It is ideal for producing consistent, high-quality vehicle parts efficiently.

This copper stamping die mold is perfect for automotive manufacturers needing precise metal parts. It can be used in workshops focused on vehicle assembly or repair. Additionally, it suits businesses looking to improve product quality through reliable stamping tools.

Precision, Durability, Customization, Finish

Custom copper stamping die molds deliver precise, high-quality Injection Molded Parts tailored for vehicle components, ensuring durability and consistent performance. With a polished finish and expert craftsmanship, these molds enhance molding accuracy and surface treatment options to meet strict automotive standards. Comprehensive packaging and assembly services further streamline production, providing efficient turnaround times and reliable protection of your design intellectual property.

● Precision

● Durable

● Flexible

● Certified

Material Introduction

This custom copper stamping die mold is crafted from high-quality copper materials that ensure excellent conductivity and durability, essential for precise and consistent molding. It is designed specifically for producing injection molded parts used in vehicle components, offering a polished finish that enhances the surface quality of the final product. The robust material choice supports efficient heat transfer and extended tool life, making it ideal for high-volume, accurate production runs.

◎ Custom Copper Stamping Die Mold

◎ High-Strength Steel Mold

◎ Aluminum Injection Mold

FAQ