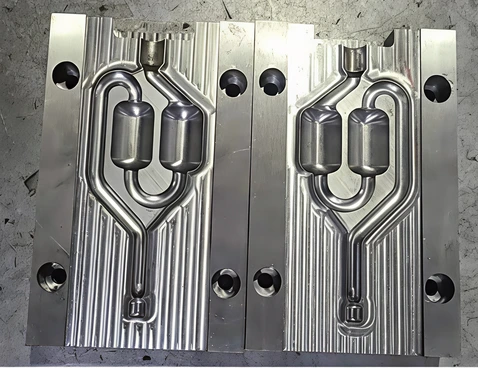

Custom Medical Plastic Blowing Mold Design and Manufacture for Liquid Tubes for Braunform

Custom medical plastic blowing molds are specially designed tools used to create precise liquid tubes for medical applications. These molds ensure high accuracy, cleanliness, and durability, meeting strict medical standards. They help produce liquid tubes that are essential for safe storage and transfer of medical fluids.

**Usage Scenarios:**

These custom molds are used to make liquid tubes for intravenous (IV) therapy, pharmaceutical packaging, and laboratory fluid handling. They are ideal for hospitals, clinics, and medical device manufacturers requiring reliable and sterile tubing solutions.

Precision, Customization, Durability, Efficiency

Our custom medical plastic blowing mold design and manufacture services deliver high-precision injection molded parts tailored for liquid tube packaging, ensuring optimal shape, style, and quality to meet stringent medical standards. By leveraging advanced CNC machining and rapid tooling, we provide fast turnaround times without compromising accuracy or durability. Additionally, our comprehensive offerings include surface treatments and full assembly, allowing you to receive ready-to-use components that enhance product performance and reliability.

● Precision

● Efficiency

● Durability

● Security

Application Scenario

FAQ