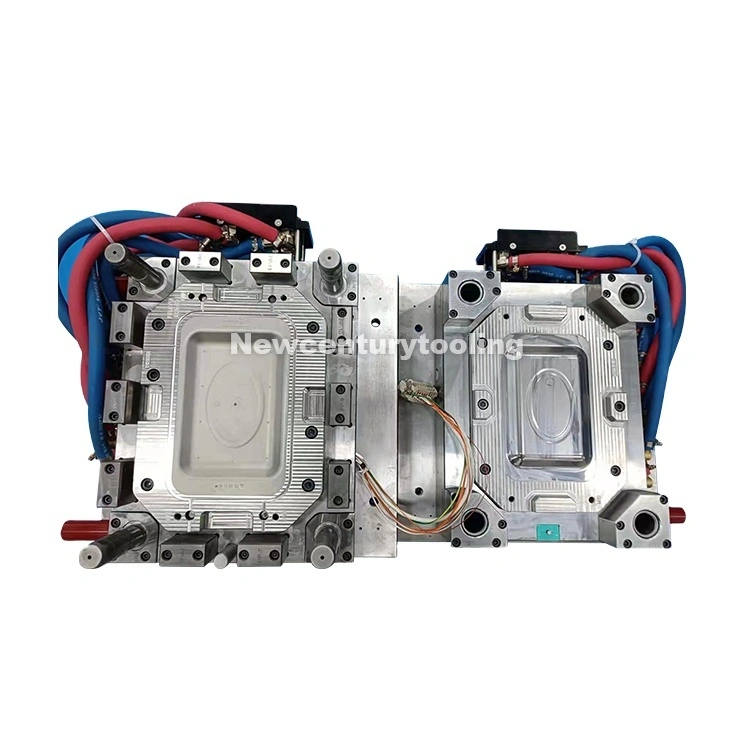

OEM ODM Injection Mold Design & Manufacturing for Kitchen Lunch Box Covers

OEM ODM Injection Mold Design & Manufacturing for Kitchen Lunch Box Covers involves creating custom molds and producing high-quality plastic covers tailored to specific client needs. This service ensures precise, durable, and food-safe kitchen lunch box covers with flexible design options. Key selling points include customized design expertise, advanced injection molding technology for consistent quality, and efficient production to meet market demands.

Custom Precision Mold Solutions

Our OEM ODM injection mold design and manufacturing service for kitchen lunch box covers delivers precise, high-quality parts with customizable shapes, styles, and surface finishes to perfectly fit your brand’s packaging and aesthetic needs. We ensure fast turnaround times through advanced CNC machining and rapid tooling processes, enabling timely production without compromising accuracy. With full assembly options and strict intellectual property protection, we support your product from concept to final delivery with reliable certification and professional craftsmanship.

● Precision

● Customizable

● Efficient

● Durable

Durable, Precise, Customizable, Hygienic

Custom Precision Durable Protection

This OEM ODM injection mold design and manufacturing service for kitchen lunch box covers offers high-precision production with tolerances ranging from 0.05 to 0.1 mm, utilizing advanced equipment such as CNC machining centers and injection molding machines to ensure consistent quality and efficiency. The product benefits from flexible surface treatment options including spray paint, silk screen, and electroplating, enhancing both functionality and aesthetic appeal. Designed for quick turnaround and full assembly support, this service emphasizes customization, IP protection, and certification compliance to meet diverse client requirements and industry standards.

◎ Precision Fit

◎ Durable Finish

◎ Flexible Service

Material Introduction

The kitchen lunch box covers are crafted using high-quality, food-grade materials suitable for injection molding, ensuring durability and safety for everyday use. The materials are compatible with precise manufacturing processes such as CNC machining and rapid tooling, allowing tight tolerances between 0.05-0.1 mm for consistent fit and finish. Additionally, these materials support various surface treatments like spray painting and silk screening to enhance the product’s appearance and functionality.

◎ Durable Plastic

◎ Heat-Resistant Polymer

◎ Treated Surface

FAQ