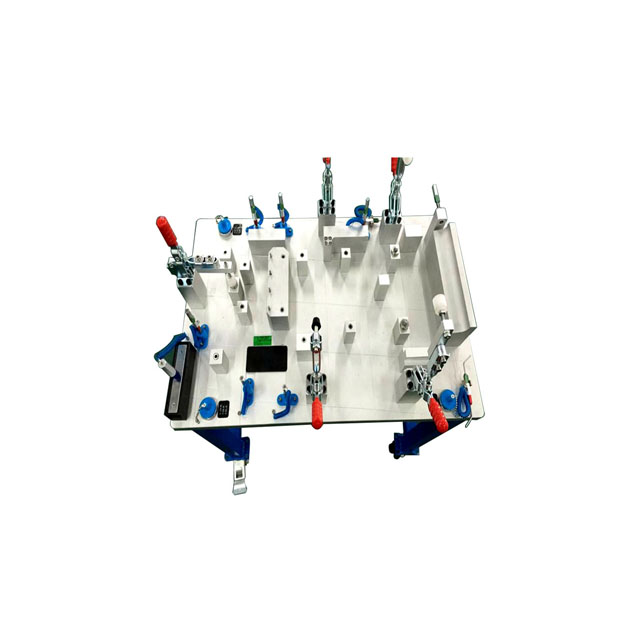

Q2. What is the accuracy of the products processed by the drawings? A2. Different equipment has different accuracy, generally between 0.05-0.1 mm.

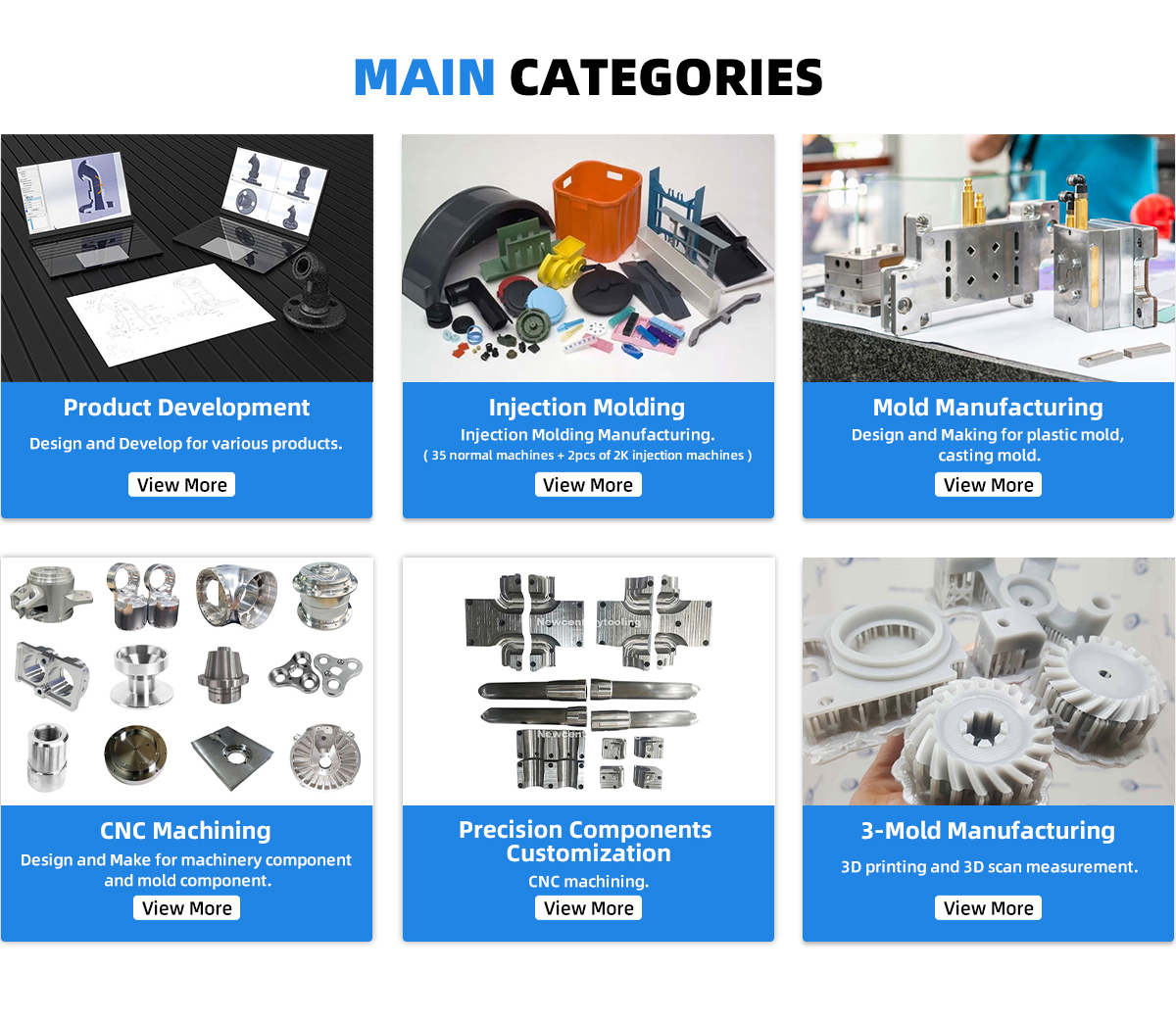

Q3. What craftsmanship do you have for processing accessories? A3. According to different products, different processes are used, such as machining, injection molding, etc.

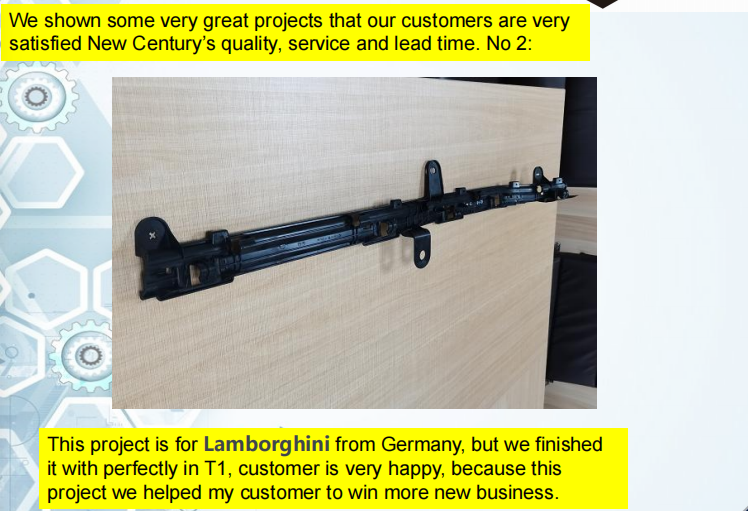

Q4. What are your processing equipment? A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,molding machine.

Q5. Can you help assembling the product after it is made? A5. It's okay . We can make the fully production, including assembly.

Q6. What certifications or qualifications does your company have? A6. Our company’s certificates are:ISO, ROHS, product patent certificates, etc.

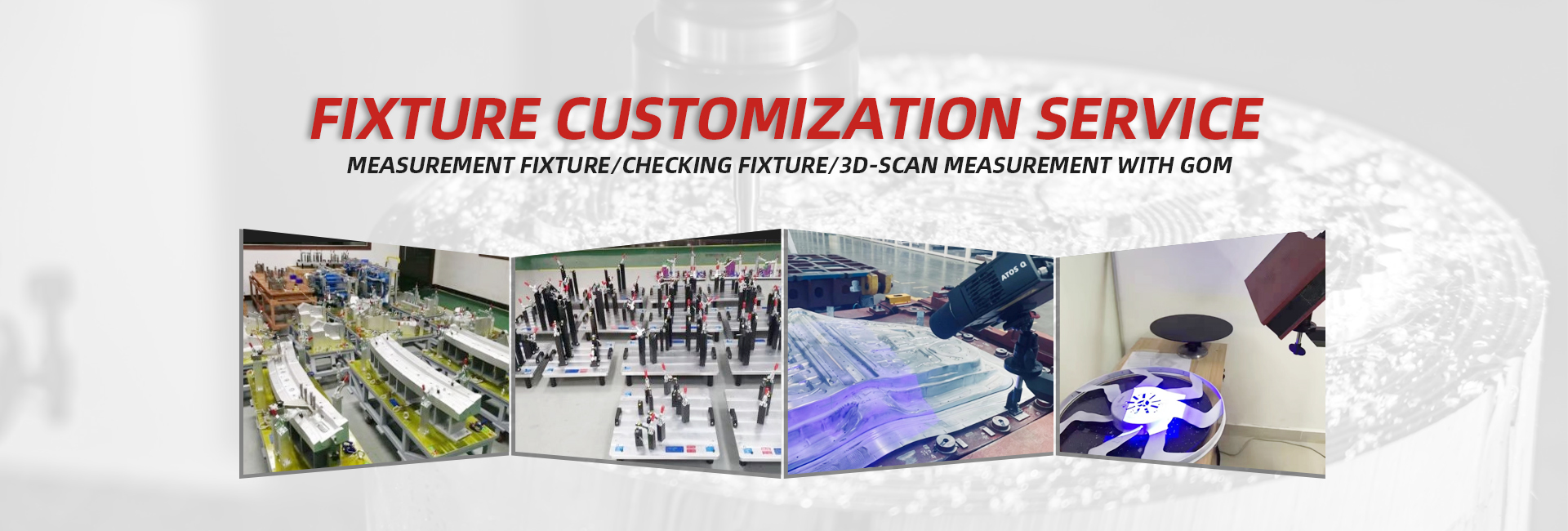

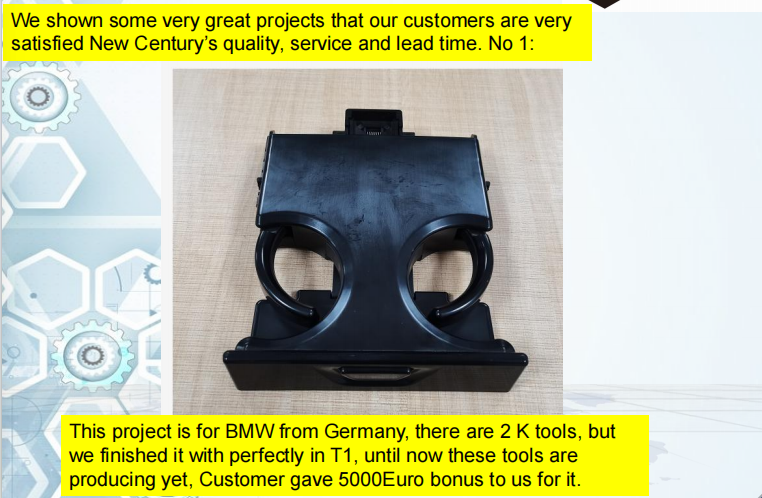

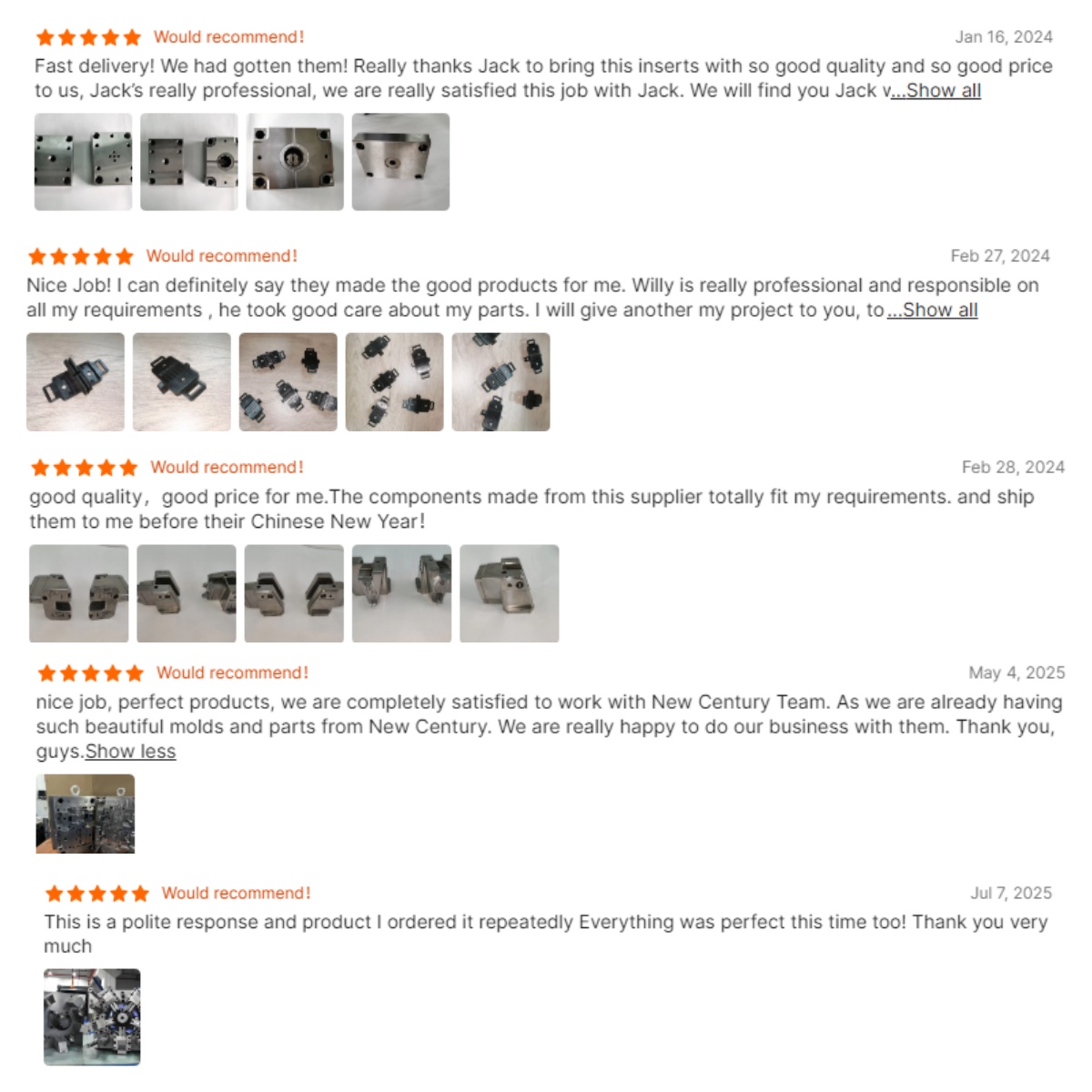

Our manufacture parts to a high standard, no matter the project or the customer.

Q7. Can injection products be surface treated? What are the surface treatments? A7. It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.

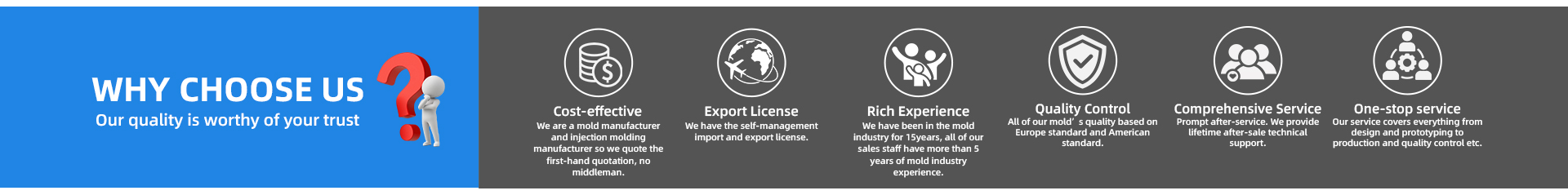

Q8. Can I request a sample? A8: For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

Q9. I want to protect my IP一Are my designs secure? We values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request, giving you peace of mind about your intellectual property.