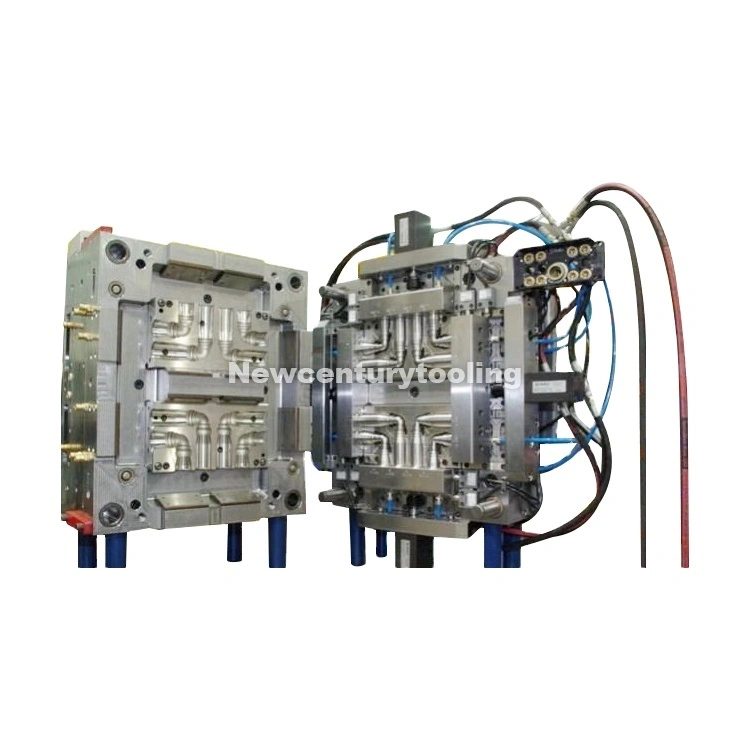

Electronic Appliance Injection Mold Manufacturing Service for Electronics

Provides precision-engineered injection molds tailored for electronic appliance components, ensuring consistent part quality and efficient production. Supports complex geometries and tight tolerances to meet the specific requirements of electronic device manufacturing.

Precision Crafting, Superior Durability

Our Electronic Appliance Injection Mold Manufacturing Service delivers high-quality injection molded parts with precise shapes, stylish designs, and durable finishes tailored to your specifications. Customers benefit from rapid turnaround times, customizable surface treatments, and strict quality control backed by ISO and ROHS certifications. Comprehensive production capabilities, including assembly and secure handling of your intellectual property, ensure a seamless experience from prototype to final product.

● Precision

● Customizable

● Efficient

● Secure

Precision, Durability, Efficiency, Innovation

Precision, Durability, Efficiency, Customization

Injection Molded Parts produced through this service feature high precision with tolerances typically between 0.05-0.1 mm, ensuring reliable dimensional accuracy suited for electronic appliance applications. These parts benefit from advanced manufacturing techniques, including rapid tooling and CNC machining, allowing for efficient production and customizable surface treatments such as spray painting, silk screening, and electroplating. The structural integrity of the Injection Molded Parts is enhanced by the use of state-of-the-art injection molding machines, supporting complex geometries and consistent quality for seamless assembly and durable performance.

◎ Precision

◎ Flexibility

◎ Integrity

Application Scenario

Material Introduction

The Injection Molded Parts produced through our electronic appliance injection mold manufacturing service utilize high-quality thermoplastic materials known for their durability, precision, and electrical insulation properties. These materials ensure that the parts meet strict dimensional tolerances and withstand the demands of electronic applications. Additionally, the molded parts can undergo various surface treatments to enhance aesthetics and functionality, making them ideal for a wide range of electronic products.

◎ High-Performance Polymer

◎ Heat-Resistant Composite

◎ Electrically Insulative Plastic

FAQ